At Safe Tech, we’re dedicated to bringing innovative technologies to the first responder and defense space. An underappreciated element of this is the manufacturing capacity our country maintains, and how vital it will be to boost these efforts as the nation recovers from COVID-19. The pandemic has made something clear to us: manufacturing is not just about creating jobs throughout the country; it should be viewed as a matter of national security.

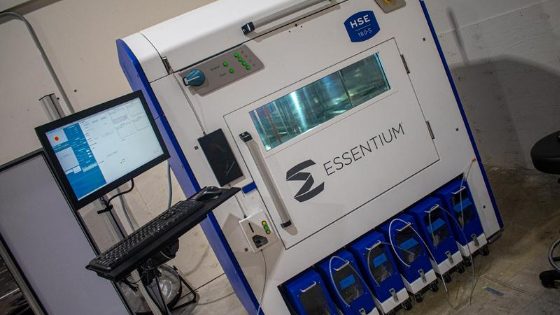

Additive@Scale is an initiative by our industry partner, Axle Box Innovations, that is disrupting the industrial manufacturing market by providing 3D printing solutions that are stronger and more efficient than existing systems. Additive@Scale combines Hexagon’s Absolute Arm, Essentium’s High-Speed Extrusion 180 (HSE) platform, and advanced materials portfolio with traditional CNC and injection molding processes. Additive@Scale’s team of engineers will design, reverse engineer, and manufacture technology that meets or exceeds existing performance standards while exponentially reducing time to part and cost of part.

Axle Box collaborates with engineers who can design, reverse engineer, and manufacture technology that will exceed specifications, increase physical properties, and improve performance. They are doing this by using the latest laser scanners and sensors for the quality control of geometries and surfaces, reverse engineering, fit and finish, and assembly applications. The use of this technology will not only speed up turnaround times, but it will also be done at a fraction of the cost of traditional methods.

The process itself is straightforward. The company utilizes Hexagon’s Absolute Arm and 3D scanning software to create high-quality scans for those parts lacking 2D drawings. The scanning software automatically generates a file that can then be put through their printing software and sent directly to its HSE printers for manufacturing. With Essentium’s high-speed extrusion process and material selection, Axle Box can print these parts with speed, agility, and strength. The company also plans to partner with injection molding firms to create 3D print molds and/or cavities to develop more agile manufacturing capabilities.

Through this program, Axle Box provides a dedicated team of engineers that can collaborate with industry and academic partners on material selection. “Our goal is to create a bridge-molding process where we will continue reverse engineering for additive manufacturing, 3D print cores and cavities, and injection mold parts with quick lead times at a fraction of the cost,” said Madison Jones, Director of the Additive@Scale Initiative for Axle Box. “Given our expertise and industry knowledge, we can create replicable processes for public safety and defense technologies, as well as general industry, to grow the U.S. manufacturing base.” In partnership with Safe Tech, they plan to display these projects in real-time at regional trade events and for government partners to demonstrate the potential impact of additive manufacturing.

The short-term goal of Additive@Scale is to highlight and display the expanding additive manufacturing community in Texas and the entire country. The group has already experienced success in reverse engineering parts for Energy Bionics’ Carbon watch and the Multi-purpose Expeditionary Platform (MPEP) from Tracks North America. But the organization isn’t stopping there – they’re ready to tackle some of the leading industrial manufacturing challenges around the country.

Given the noted supply chain issues observed with COVID-19, Axle Box’s ability to provide solutions with local partners will be at the forefront of technological innovation by relying on industrial-scale 3D printing and additive manufacturing techniques. The company is leading the way in enhancing public safety by reducing the risk of manufacturing disruptions brought about by overseas manufacturing partners during the pandemic. The localized solution provides an opportunity for regional manufacturing growth throughout the country, further reducing disruption risks in the U.S. itself.

Be sure to follow Axle Box as it expands in this area. We’re looking forward to seeing Additive@Scale grow!

We’re dedicated to making this dream a reality – won’t you join us?